Increasing demand for New Energy technologies – predominantly battery storage – is an ongoing, common trend in many industries including electric vehicles (EVs), heavy haulage, public transport and renewable generation projects. As this demand increases, so too does the demand for the metals and minerals which form these technologies, and the pressure on the mining sector to provide a constant supply.

In this article, we identify the materials that are in high demand and the fundamental role played by the mining sector in the New Energy transition. We also consider the key issues facing this transition, mainly in the form of supply chain shortages, and look at some of the steps to achieve market balance for these materials in the future.

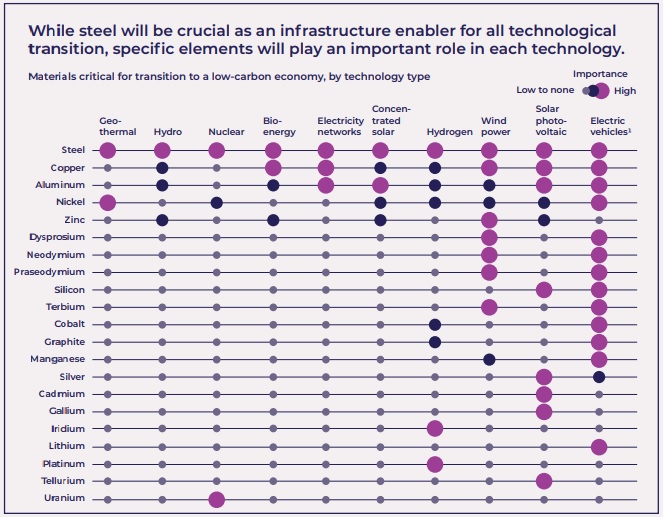

1Includes energy storage. Source: Critical raw

materials for strategic technologies and sectors in the EU, A

foresight study, European Commission, Mar 9, 2020; The role of

critical minerals in clean energy transitions, IEA, May 2021;

McKinsey analysis

The Building Blocks of the New Energy Transition

Several raw materials are at the core of enabling the New Energy transition. Copper is a valuable material in bioenergy, electricity networks, wind power and solar photovoltaic technologies and in the manufacture of EVs. Wind, solar and electricity-powered technologies are also highly reliant on a range of other raw materials including aluminium, and neodymium. The required pace of transition means that the availability of these materials will need to be scaled up within a relatively short time scale and, in certain cases, at volumes ten times or more than the current market size to prevent shortages and keep new technology costs competitive.

Certain metals and raw materials increase the performance of these technologies for longer periods of time, which in turn maximises efficiency and sustainability while reducing waste. Lithium metal anode, for example, is used to boost energy density in batteries, allowing the battery to perform better and for longer compared to a graphite anode alternative.

Battery Manufacturing

The following minerals are used in battery manufacturing:

Lithium – a key ingredient to produce traction batteries used in EVs and other consumer electronics; it is also used in energy storage and air mobility technology.

Cobalt and nickel – cobalt prices peaked at $100,000 / metric ton in 2018, leading to a switch to nickel, which similarly grew more expensive and proved ineffective in facilitating maximum design capacity. Currently, both materials are less commonly used.

Manganese – a useful alternative to cobalt and nickel for its sheer abundance in global production and supply (4-5x greater than nickel production and 140x greater than cobalt productioni), plus reserves.

Supply Chain Issues

In the short-term, the outbreak of war in Ukraine and the ongoing energy crisis have forced countries around the world to reassess their reliance on fossil fuels, particularly when imported from overseas. Renewables, most notably in the form of wind and solar power coupled with battery storage and/or green hydrogen production, are going to be increasingly important in providing energy security.

Therefore, while increasing renewable energy capacity seems an obvious solution, high prices, the challenges in bringing projects to production, the cost of new technology and uncertainty in the supply chain are growing concerns for the New Energy sector.

These supply issues may also be exacerbated due to other factors such as:

- Environmental trends favouring certain renewable energy generation – for example, where solar panels may not be performing well due to weather or seasonal changes, there may be a shift towards wind-generated power and accordingly, an increased demand for neodymium; and

- Greater volume of raw materials for sustainable technologies compared to fossil fuel-based alternatives – renewable energy capacity is generally lower than its fossil fuelbased counterpart (eg an EV needs about six times more minerals than a petrol-powered car), therefore more raw materials are needed to generate the same amount of energy.

One method of achieving future market balance in supply and demand is refining the existing methods for extracting raw materials and being willing to explore alternative extraction sites. This method can help to balance future supply and demand by maximising the safe intake of raw materials from each site and reducing supply time delays, leading to lower financial and environmental costs in the long-term. However, this depends on a number of factors including the location of the relevant sites and the technology required to be applied, which is often new and developing. An example of this is in China, where companies have invested in new hard rock and brine lithium projects over the past few years, but there remains a question mark as to the quality of these resources and their ability to produce battery-grade product.

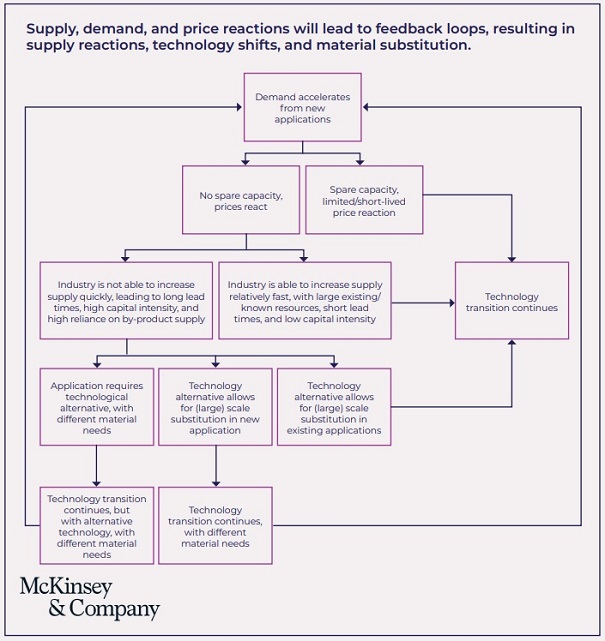

Alternatively, technological innovation may accelerate to the point of being able to make material substitutions in the case of any deficit, reducing the pressure to supply one specific material altogether. In either case, sufficient capital investments both at Government and industry level will be necessary for these innovative measures.

The table below illustrates the supply and demand imbalance issue in more detail, including potential solutions:

Australia's Prime Position

The supply chains for critical minerals will be dominated by the switch to renewables. The International Energy Agency's most conservative forecasts expect demand for lithium to grow 13- fold in the 20 years to 2040, rare earth demand to triple, copper to double and cobalt is expected to increase at least six times.

Whilst acknowledging the recent press from some of the investment banks in relation to a lithium over-supply as a result of the number of projects potentially being brought to production, the broader industry view appears to reflect a position that any balance in the supply and demand of lithium, and in particular battery-grade product, is more likely to be some years away.

Australia is well positioned to supply these critical minerals and in doing so can make a huge contribution to combat climate change globally. For instance, Australia has rapidly become the world's biggest exporter of lithium by producing almost half of the worldwide supply.

As Australia still exports the majority of its critical minerals overseas, there is an opportunity for midstream processing to be undertaken locally. At present, particularly in rare earths, this midstream processing market is heavily dominated by China. Countries including Australia have begun to make a concerted effort to encourage midstream processing onshore, with grants and other incentives being offered in a bid to create an industry and additional jobs. For instance, a $120 million deal for a commercial-scale processing facility was recently struck between Australia's Lynas Rare Earths and the U.S Department of Defence, to operate in Texas by 2025. This deal is particularly significant as it creates a secondary supply chain for the processing of heavy rare earths elements outside of China.

Australia's mining industry also has a strong incentive to adhere to strict environmental standards and technological advancement is on foot to develop new methods that allow us to mine these important minerals sustainably.

Government Assistance

On 4 April 2022, the Federal Government approved a $1.25 billion loan to Iluka Resources to develop Australia's first integrated rare earths refinery in Western Australia. This is a crucial step under the Government's Critical Minerals Strategy, which aims to turn Australia into a global critical minerals powerhouse by 2030.

The refinery will produce rare earth oxide products such as neodymium and terbium, which are used in the manufacture of EVs, clean energy generation and defence technologies. The refinery project is projected to secure Australia's manufacturing capability and provide a range of job and economic opportunities in the New Energy space.

In the future, the refinery project will be further supported and sustained under the Government's Modern Manufacturing Strategy, which will seek to explore potential offtake and investment opportunities to continue meeting the increasing global demand for critical minerals. As part of this strategy, the Federal Government has announced a series of grants through its $1.3 billion Modern Manufacturing Initiative which aims to support midstream projects.

A Sustainable Transition

The transition to a net-zero, clean energybased economy will be heavily reliant on rare earths and critical minerals. A rush to make the switch will place a strain on critical mineral reserves, resulting in a range of issues from disproportionate supply and demand to material shortages and high costs for products. However, with technological innovation, advances in extraction methods and sufficient Government and private capital investment, the transition to a New Energy society should be secured.

The content of this article is intended to provide a general guide to the subject matter. Specialist advice should be sought about your specific circumstances.