The Indian footwear industry, a dynamic and expansive sector, has achieved remarkable growth, solidifying its position as the world's second-largest footwear manufacturing hub, rivalled only by China. Notably, it contributes to 13% of global footwear exports.

The recent governmental requirement mandating the compliance of the footwear industry with BIS standards serves a dual purpose: fostering industry growth and safeguarding its competitive edge. As the Indian footwear sector experiences a paradigm shift due to the enforcement of Quality Control Orders (QCOs) across various footwear categories by the Bureau of Indian Standards (BIS), footwear brands and manufacturers are confronted with a pivotal juncture. They must harmonize prompt compliance with the least possible disruption to their operations. This pivotal development doesn't just pose challenges; it also unveils unprecedented prospects for brands establish themselves as pioneers in quality, safety, and innovation within this ever-evolving domain. Given that nearly 50% of domestic footwear manufacturers operate within the unorganized sector, the government's proactive move to institute quality benchmarks for footwear generates a conundrum. This conundrum revolves around meeting timelines for implementation of these standards while effectively managing business expectations.

Given the above background, this article attempts to address key questions on the requisite requirements to obtain BIS license for the footwear industry.

Who should obtain the licence?

Currently, the biggest challenge being faced by all the relevant industry players is to understand and identify the entity that is liable to obtain the licence. Clarity is also sought on the categorisation of footwear on the basis of applicable Indian standards (IS) and QCO.

At the outset, the license is issued for the manufacturing plant where the final manufacturing activity is undertaken and not the brand that is introducing or designing the product itself. Further, the BIS issues distinct licenses for each variety of products based on the classification under relevant Indian standards. For instance, if a manufacturing unit produces both sports footwear for general purpose (i.e. covered under IS 15844 part 1: 2023) and hawai chapal (i.e. covered under IS 6721:2023), it is essential to acquire separate licenses for each product which is covered under different Indian Standards. It is crucial to note that manufacturers owning multiple units with different factory licences are required to obtain licenses for each distinct unit, even if they produce the same goods.

Therefore, while different variations of a product might fall under the same Indian standard and license, it is recommended that manufacturers do a precise categorization ( in alignment with the relevant product manual issued for specific footwear products). By adhering to this practice, potential risks can be effectively curtailed, pre-empting any setbacks such as license delays or cancellations.

Notably, licensing is mandatory for both domestic and foreign footwear manufacturers catering to the Indian consumer market. Even though the importers, distributers, sellers, etc. are not required to obtain the licence, they should verify whether the manufacturer holds a valid BIS licence before procuring or marketing such products which are covered under the compulsory licencing scheme of BIS license.

Coverage under various QCOs on footwear

As of 2023, after multiple revisions and extensions, the government listed 27 products under the 3 QCOs initially introduced in 2020. Certification is mandatory for these products:

|

QCO |

No. of Products |

Date of Implementation |

|

Personal Protective Equipment – Footwear QCO |

03 |

1st Jan 2022 |

|

Leather and other Materials Footwear QCO |

11 |

1st July 2023 |

|

All rubber and all polymeric material footwear QCO |

13 |

1st July 2023 |

Standards for certain products have been revised recently and the manufacturers making the products as per these revised specifications/standards will be given an additional time of 6 months to comply i.e. up to 31 December 2023. The products are listed below:

|

Current IS No. (Product) |

Revised IS No. (Product) |

|

IS 15844: 2010 – Sports footwear |

IS 15844 (Part 1):2023 – Sports Footwear Part 1 – General Purpose and IS 15844 (Part 2): 2023 – Sports footwear Part 2 Performance Sports Footwear |

|

IS 10702: 1992 – Rubber Hawai Chapal |

IS 10702: 2023 – Hawai Chapal |

|

IS 11544: 1986 – Rubber Slipper IS 6721: 1972 – PVC Sandal |

IS 6721: 2023 – Sandal and Slipper |

Further, at present, Micro and Small-Scale enterprises (defined in the MSME Act) have not been covered under the scope of QCOs for "All-Rubber and all Polymeric materials and it's components and Leather and other materials." Small-scale enterprises will be covered under the prevalent QCO from 1st January 2024 and microscale enterprises will be covered from 1st July 2024. Henceforth, these enterprises shall not manufacture, import, distribute, sell, hire, lease, store or exhibit for sale any product(s) covered under the QCO without the Standard Mark after the relevant dates.

Relaxation on testing requirements

Moreover, on the requests and comments received by the industry players regarding the steep cost of testing equipment used in the testing of the footwear, the BIS has allowed a relaxation in testing facilities under the Guidelines of Grant of licence. A significant respite has been extended to manufacturers. In cases where a grouping of manufacturing units is geographically concentrated and expresses interest in utilizing a centralized testing facility, they may now seek permission to proceed accordingly.

Gearing up to Comply with Indian Standards

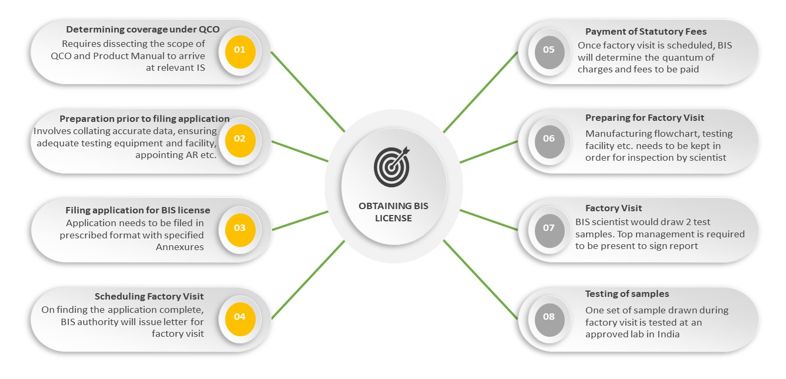

India's Conformity Assessment Regulations, 2018 stipulate the procedure for obtaining BIS certification which can be briefly viewed in the chart below:

In conclusion, the quality control standards for the footwear industry, offer a a promising opportunity for manufacturers to compete fairly in an unadulterated market, devoid of counterfeit products. This not only creates brand value for Indian manufacturers but also ensures customer satisfaction and loyalty. To capitalize on this, manufacturers must align with relevant QCOs on footwear and Indian standards.

The BIS certification stands not only as a testament to their unwavering dedication to consumer well-being but also as a decisive pathway to garner broader market recognition. For those brands with aspirations set on international horizons, the observance of rigorous quality benchmarks takes on an even more pivotal role. The BIS quality control order harmonizes seamlessly with global quality norms, consequently amplifying the export prospects of Indian footwear brands. In essence, this scenario unfurls an exciting opportunity for expansion that extends far beyond domestic confines.

Ensuring compliance with the BIS is crucial from a legal perspective due to implications under various regulations such as Customs law and Government incentive schemes. Therefore, it is important for the industry to expedite compliance with the relevant QCOs on footwear.

The content of this article is intended to provide a general guide to the subject matter. Specialist advice should be sought about your specific circumstances.